Equipment and options

DinesDuo ensures the highest quality standards.

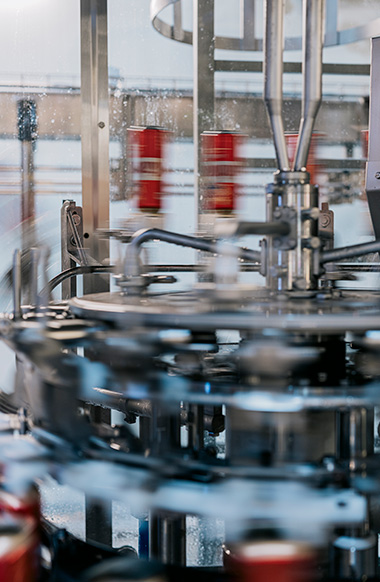

Separate production lines

We simultaneously work on three separate production lines, depending on the type of products we are bottling. This allows us to particularly make sure that products with a more delicate flavor and more intense products are kept separate.

Automated facility

Innovations and technologies have allowed us to equip our bottling facilities in line with the state-of-the-art standards applied in other European facilities.

Innovation

Our engineers have years of experience and specific knowledge that they implement daily in the facility’s operation. Thanks to them, our bottling facility can measure up to any modern European facility – both in terms of the bottling process and the technologies employed.

Our solutions

We approach all clients individually and strive to fulfill their specific requests. Our job does not end once the bottling process is finished. We can offer advice throughout the process – from product branding to its distribution to end consumers.

Storage and Logistics

Loading

Unloading

Consolidating

Storage

Sorting

Packaging

Measuring

Weighing

It is very important that the client makes a good decision on the type of packaging. This is part of product branding, and is used to attract and inform consumers. The role of packaging is also to protect the product.

Bundle wrapping and transport wrapping are particularly important for any storage facility.

Packaging needs to allow stacking both in the warehouse and in the retail environment. It is important that the product gets to the customer completely undamaged. Our transport packaging includes Euro-pallets mechanically wrapped in stretch foil, and ensures quick loading and safe transport of products.